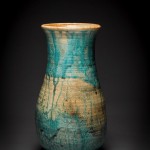

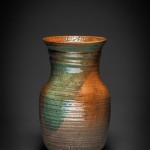

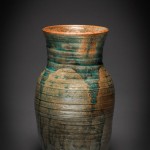

Post-firing Reduction

With a post-firing reduction process, each piece is different and I never know what the piece will look like until the firing is completed. It is a rapid firing process where pieces are fired in an outdoor kiln, quite quickly (2-3 hours). Pieces are then individually taken from the kiln, still hot, and surrounded by combustible material to flame, then smoke. Unveiling the piece and scrubbing it clean reveals the wonders of the fire as well as changes due to glaze application, the fire itself, and the effect of the smoke and flame.

This process was discovered by accident in 1960 by American professor Paul Soldner during a demonstration of the Japanese Raku process. The piece he was moving from the kiln to the quenching bath fell into some dried leaves and ignited them. He liked the results, so the post-reduction process was born.

Pieces are water tight but are not food safe. Best to wash by hand with warm, soapy water.

All photographs © Marvin Moore Photography.

- “Couple”

- Vase

- Vase

- Vase

- Vase

- Vase

- Vase

- Vase

- Vase

- Vase

- Vase

- Vase

- Vase

- Vase

- Vase

- Container

- Vase

- Vase

- Vase

- Vase

- Vase

- Vase

- Container with lacquer lid

- Container

- Container

- Container

- Container

- Bowl

- oted bowl with gold leaf

- Wall Platter

- Vase

- Vase